A Complete Guide to Traditional, Modern & Technology-Driven Bangle Making

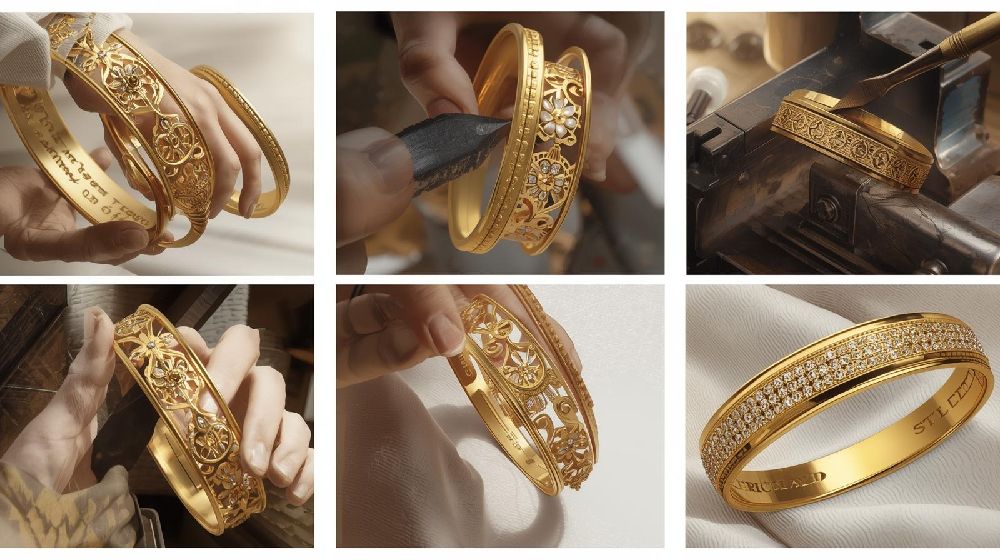

Gold bangles are one of the most iconic pieces of jewelry across cultures. From classic handcrafted kada designs to modern CNC-finished bangles, each style carries its own identity — and each requires a different manufacturing technique.

Whether you are a jewelry lover, a retailer, or part of the gold manufacturing industry, this guide explains the most popular types of gold bangles and how every style comes to life inside the workshop.

✨ Why Understanding Bangle Types Matters

Every bangle differs in:

-

Production time

-

Manufacturing technique

-

Strength & durability

-

Design complexity

-

Weight & gold wastage

Knowing these helps customers choose better and helps jewelers explain craftsmanship more effectively.

1. Solid Bangles — The Classic & Timeless Style

What Are Solid Bangles?

Solid gold bangles are made from a continuous circle of gold with no hollow space inside. They are durable, long-lasting, and traditional.

How They Are Manufactured

-

Gold is melted and cast into rods.

-

Rods are rolled to the required thickness.

-

Craftsmen bend the rod into a circular shape.

-

The ends are welded using torch or laser welding.

-

Final shaping, sizing, and polishing complete the piece.

Best For: Bridal sets, premium collections, traditional wear.

2. Hollow Bangles — Lightweight & Budget-Friendly

What Are Hollow Bangles?

Hollow bangles look solid but are empty inside. They offer bold designs with much lighter weight.

Manufacturing Process

-

Thin gold sheets are rolled into tubes.

-

Tubes are shaped into bangles using forming machines.

-

Precision welding seals the tube perfectly.

-

CNC or laser machines may add external patterns.

-

Final polishing gives a shiny, finished look.

Best For: Daily wear, fashion collections, gifting.

3. Casting Bangles — Bold, Detailed & Artistic

What Are Casting Bangles?

These bangles are made through the casting process, allowing complex shapes, textures, and artistic details.

How They Are Manufactured

-

Designers create a 3D CAD model.

-

The model is printed in wax.

-

Wax tree is created for mass production.

-

Investment casting forms a mold.

-

Molten gold is poured inside.

-

After cooling, the mold is broken, and the bangle emerges.

-

Filing, soldering, finishing, and polishing are done manually.

Best For: Designer bangles, textured patterns, stone-studded styles.

4. CNC Bangles — Precision Cut & Modern Luxury

What Are CNC Bangles?

CNC (Computer Numerical Control) bangles feature sharp, geometric, and diamond-cut-like patterns created by machines.

Manufacturing Method

-

Start with a solid or hollow tube.

-

CNC machine cuts micro-designs with extreme precision.

-

Multi-axis movement creates 3D and 4D patterns.

-

Laser finishing enhances shine and sharp edges.

Best For: Modern, stylish bangles with brilliant sparkling effects.

5. Laser-Welded Bangles — Seamless & Highly Durable

What Makes These Special?

Laser welding creates invisible joints, increasing strength and providing a clean, flawless finish.

Manufacturing Steps

-

Components are made separately (body, edges, joints).

-

High-precision laser welding joins them.

-

This avoids excess heat and prevents damage.

-

Final polishing ensures no visible seam or line.

Best For: High-quality premium bangles, especially openable bangles.

6. Openable Bangles — Practical & Stylish

What Are They?

These bangles come with a hinge and lock system, making them easy to wear and remove.

How They Are Manufactured

-

Bangle is crafted in two halves (casting or CNC).

-

Hinges and locks are made separately using micro-components.

-

Laser welding is used to assemble fine parts.

-

Final checking ensures lock strength and smooth movement.

Best For: Daily wear bangles, elderly customers, bridal pieces.

7. Kada Bangles — Thick, Bold & Cultural

What Is a Kada?

A kada is a thicker, often wider bangle, sometimes for men, designed with heavy patterns or plain finishes.

Manufacturing Technique

-

Created using forging, rolling, or casting.

-

Heavy polishing tools give a smooth or hammered finish.

-

Sometimes laser engraving or CNC detailing is added.

Best For: Traditional wear, men’s jewelry, temple-style designs.

8. Flexible Bangles — Smooth, Comfortable & Trendy

What Are Flexible Bangles?

Made with multiple small joints or wires, flexible bangles easily adjust to wrist movement.

Manufacturing Process

-

Thin wires or micro-links are crafted individually.

-

Each link is laser-welded or joined with precision.

-

Gold tubes and springs may be used for flexibility.

-

Polishing and cleaning complete the piece.

Best For: Modern fashion jewelry, lightweight collections.

9. Textured Bangles — Matte, Hammered, Gloss & More

What Makes Them Unique?

Textures enhance personality using surface design.

How They Are Made

-

Matte by sanding or blasting

-

Gloss by high-speed polishing

-

Hammered by hand tools

-

CNC by machine engraving

Best For: Stylish women, gifting, designer collections.

✨ Final Thoughts: Choosing the Right Bangle Style

| Bangle Type | Key Features | Manufacturing Method |

|---|---|---|

| Solid | Strong & timeless | Rolling + welding |

| Hollow | Lightweight | Tube forming |

| Casting | Detailed designs | Investment casting |

| CNC | Precision patterns | Machine engraving |

| Laser-Welded | Seamless joints | Laser technology |

| Openable | Easy-to-wear | Hinges + locks |

| Kada | Bold & heavy | Forging/casting |

| Flexible | Comfortable | Links + wiring |

| Textured | Surface designs | Manual/CNC finishing |

Each type reflects a different blend of craftsmanship and technology. Understanding these makes it easier to choose the right bangle — whether for retail, manufacturing, or personal style.